flexo printing machinery for label

1-1000 Set

$42,000.00

≥ 1001 Set

$8,000.00

- Item No.20210317803ffMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

1. Easy operation, accurate color register, high quality can be sure long time use

2. Adopts Taiwan motor, Japanese inverter, save power, smooth running.

3. Automatic stop ink pump motor when down printing roller, automatic run ink pump motor when lift printing roller.

4. Adopts closed doctor blade

5. Bevel wheel transmission makes accurate printing size

6. Use blower and heating double drying device, Constant temperature control device set inside the heating device,

control every unit , cool blower fixed shape.

7. Germany special iron material make the roller, after special treatment, electroplate 100mic thickness hard-chrome protection layer

8. Aluminum guid roller get treatment of rigid oxidation, moving balance, motionless balance.

9. Taiwan air shaft load material( optional)

10. Tension control for rewinding and unwinding unit ( optional)

>>Our Service

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

2.Clients Traning Services

We can train your staff to use your film blowing equipment systems properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

>>Main Technical Parameters:

| Item/ Printing width | 600MM | 80MM | 1000MM | 1200MM | 1400MM | 1600MM | 1800MM | 2000MM |

| Printing color | 4 colours (PC:6+0; 5+1;4+2;3+2) | |||||||

| Printing width | 7.5"-40"/7.5"-50"/7.5"-60"/7.5"-70"/7.5"-80" | |||||||

| Printing plate lifting system | Pneumatic/Hydraulic press control/Menu | |||||||

| Mechanical speed | 100m/min | |||||||

| Printing speed | 80m/min | |||||||

| Anilox cylinder | Metal: 10DK-120DK (Germany) | |||||||

| Register precision | Longitude:±0.25mm Transverse:±0.25mm | |||||||

| Rewinder/Unwinder DIA | Φ 600mm | |||||||

| Master motor (kw) | 3.0 | 3.0 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 |

| Unwinder motor (kw) | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3.0 | 3.0 |

| Rewinder motor (kw) | 1.5 | 1.5 | 2.2 | 2.2 | 3.0 | 3.0 | 3.7 | 3.7 |

| Electrical header (kw) | 14 | 16 | 20 | 22 | 24 | 26 | 28 | 30 |

| Blower of heater(kw) | 1.5*2 | 1.1*3 | 1.1*3 | 1.1*3 | 1.5*3 | 1.5*3 | 2.2*3 | 2.2*3 |

| Blower of nature wind (kw) | 0.75 | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 |

| Inking motor (W) | 750 | 750 | 750 | 750 | 750 | 750 | 750 | 750 |

| Master frequency converter | Panasonic/ Toshiba transducer Japan | |||||||

| Bearing | Janpan (NSK) | |||||||

| Unilateral bearling | ASNU(Germany) | |||||||

| Weight(kg) | 3500 | 3750 | 4000 | 4250 | 4500 | 4750 | 5000 | 5300 |

| Total power(kw) | 20 | 22 | 26 | 28 | 34 | 37 | 45 | 48 |

| Dimension(L*W*H)m | 4.5*1.8*2.5 | 4.5*2.0*2.5 | 4.5*2.2*2.6 | 4.5*2.4*2.6 | 4.5*2.6*2.7 | 4.5*2.8*2.7 | 4.5*3.0*2.7 | 4.5*3.2*2.7 |

1. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc. Prepared)

2. How many days will you finish installing ?

We will finish installation and training within 15 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee for electricity parts and two years guarantee for mechanism, starting from finished installation.

5. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

6. How could you do after one year warranty period?

We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Does your engineer understand English?

Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

9. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

| Business Type | Manufacturer, Trading Company | Country / Region | Zhejiang, China |

| Main Products | Circular Loom,Lamination Machine,Bag Making Machine,Nonwoven Bag Making Machine,Printing Machine | Total Employees | 51 - 100 People |

| Total Annual Revenue | confidential | Year Established | 2011 |

| Certifications | CNAS | Product Certifications | Utility Model Patent Certificate ,CE,CE,CE,CE |

| Patents | Trademarks | ||

| Main Markets | Domestic Market 30% Southeast Asia 17% Africa 15% | ||

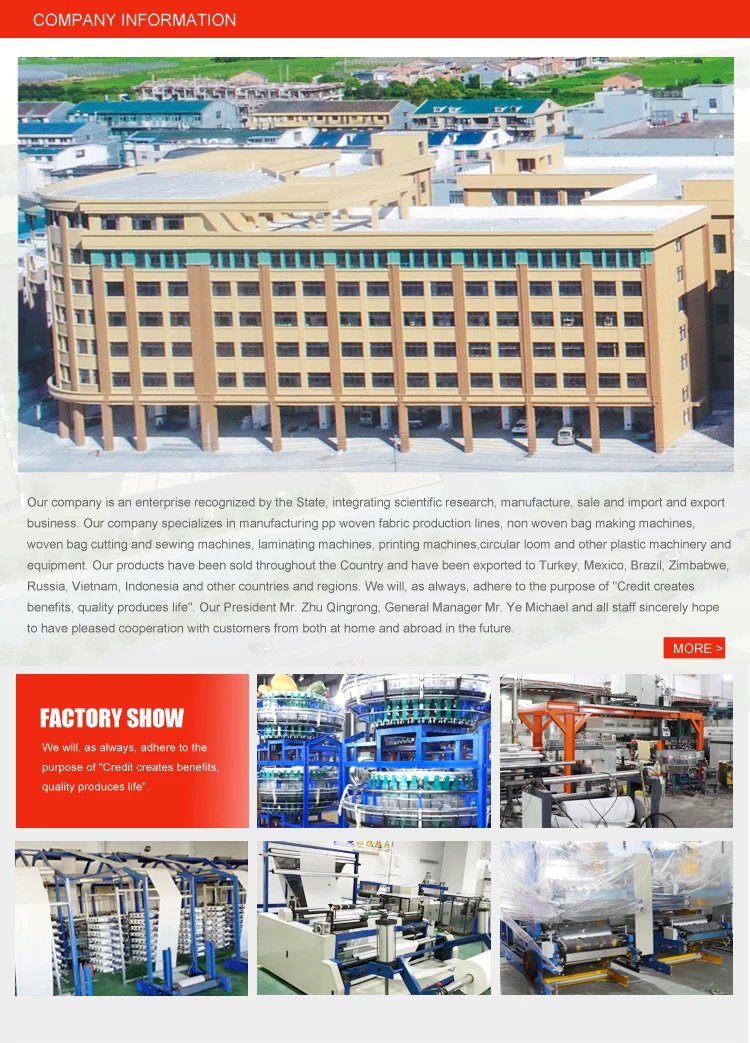

Our company is an enterprise recognized by the State, integrating scientific research, manufacture, sale and import and export business.

Our company specializes in manufacturing pp woven fabric production lines, non woven bag making machines, woven bag cutting and sewing machines, laminating machines, printing machines,circular loom and other plastic machinery and equipment. Our products have been sold throughout the Country and have been exported to Turkey, Mexico, Brazil, Zimbabwe, Russia, Vietnam, Indonesia and other countries and regions.

We will, as always, adhere to the purpose of "Credit creates benefits, quality produces life". Our President Mr. Zhu Qingrong, General Manager Mr. Ye Michael and all staff sincerely hope to have pleased cooperation with customers from both at home and abroad in the future.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian