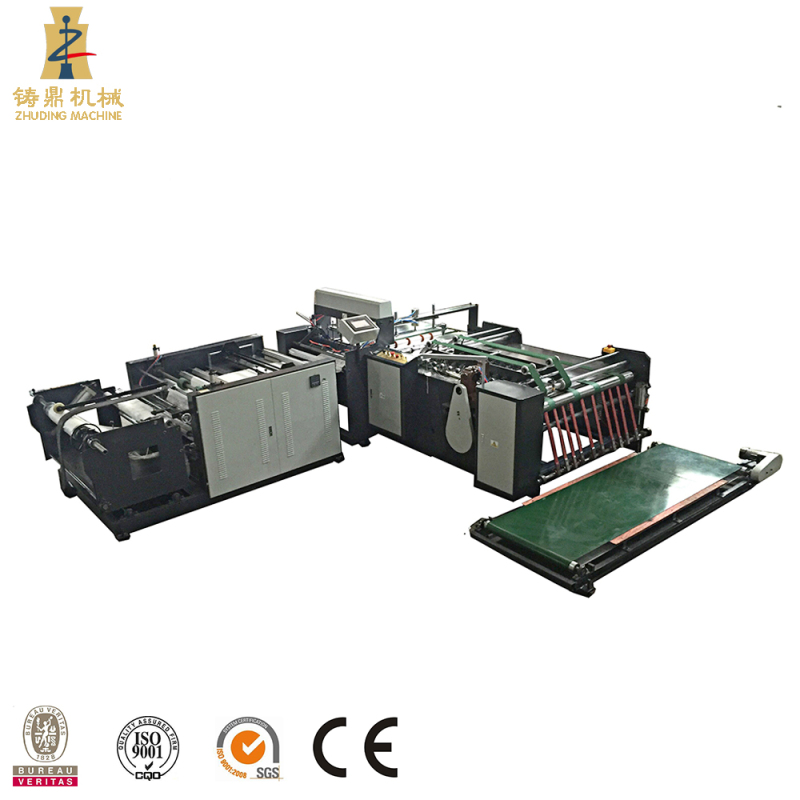

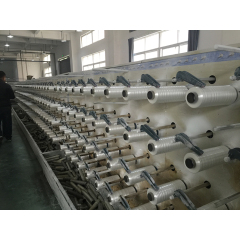

Polypropylene tape PP woven bag plastic extruder fabric production line

≥1 Piece

$100,000.00

- Item No.202103172848aMOQ1 Piece

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Performance and Characteristics

The flat yarn making machine is adopted micro-processor control, frequency conversion governor and setting andisplaying technical data may be fully digitized on the basis of absorbing international advanced teparts use quality products. The line enlarges L/D ratio and adopts new type of separating screw and widens mixing smezone on the extruder screw pot which is specially processed using quality steel, fine plasticized effect, low energyconsumption Changing filter system ofg line, we apply advanced automatic bechangehe bake-board is changed into advanced hot drawing oven and principal technical index of the line reachesernational advanced level. The winding machine is of friction-free drive and constant tape tension wind, good formatione Ine has the performance OT high speed, top yleld, low energy consumption, good Forming quaber drum. The structure of the line is compact wticated manufactngineering, convenient operation and reliable production, it can be used in producingflat fiber form thermoplastic, such as polypropylene(PP)and high-density polyethylene(HDPE)etc

| Type | Max extrusion volume | Driving powerof extruder | Screw diameter | Ratio of L/D | Revolution of screw | Die lip width | Max productiona speed |

| ZD-SPL-70/33/850 | 180kg/h | 45kw | 70mm | 33:1 | 20-120r/min | 850m/min | 280m/min |

| ZD-SPL-90/33/1000 | 280kg/h | 90kw | 90mm | 33:1 | 20-120r/min | 100m/min | 280m/min |

| ZD-SPL-100/33/1100 | 350kg/h | 90kw | 100mm | 30:1 | 20-120r/min | 1100m/min | 280m/min |

| ZD-SPL-120/33/1500 | 490kg/h | 160kw | 120mm | 30:1 | 20-120r/min | 1500m/min | 280m/min |

| Type | Flat thread fibre scope | Drawing ratio | Number of winder (Spindles) | System installed capacity | Syetem normal operational capaciy | Overall dimensions(L*W*H) | Weight(kg) |

| ZD-SPL-70/33/850 | 60-200tex | 4-10 | 144 | 240kw | 128kw | 2700*3700*2800 | 21000 |

| ZD-SPL-90/33/1000 | 60-200tex | 4-10 | 176 | 300kw | 160kw | 3500*3700*3000 | 28000 |

| ZD-SPL-100/33/1100 | 60-200tex | 4-10 | 192 | 320kw | 170kw | 3400*3700*3000 | 30000 |

| ZD-SPL-120/33/1500 | 60-200tex | 4-10 | 256 | 400kw | 210kw | 3700*3900*2600 | 32000 |

1. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc. Prepared)

2. How many days will you finish installing ?

We will finish installation and training within 15 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee for electricity parts and two years guarantee for mechanism, starting from finished installation.

5. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

6. How could you do after one year warranty period?

We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Does your engineer understand English?

Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

9. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

| Business Type | Manufacturer, Trading Company | Country / Region | Zhejiang, China |

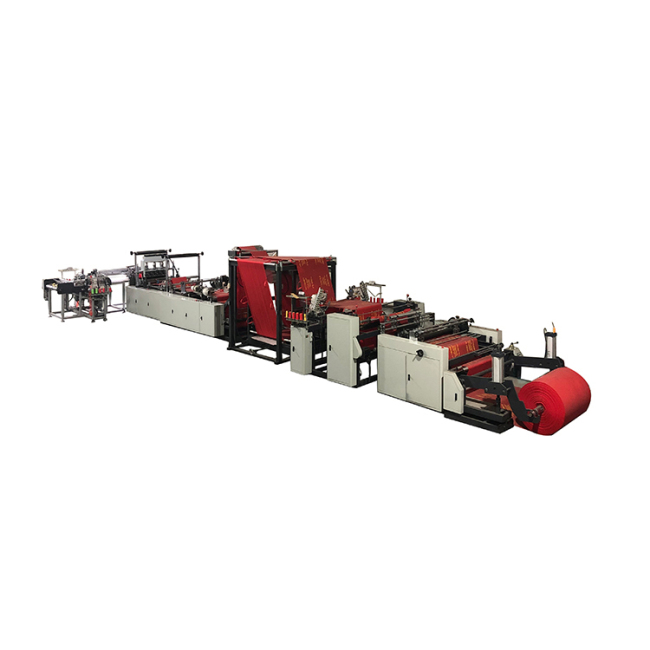

| Main Products | Circular Loom,Lamination Machine,Bag Making Machine,Nonwoven Bag Making Machine,Printing Machine | Total Employees | 51 - 100 People |

| Total Annual Revenue | confidential | Year Established | 2011 |

| Certifications | CNAS | Product Certifications | Utility Model Patent Certificate ,CE,CE,CE,CE |

| Patents | Trademarks | ||

| Main Markets | Domestic Market 30% Southeast Asia 17% Africa 15% | ||

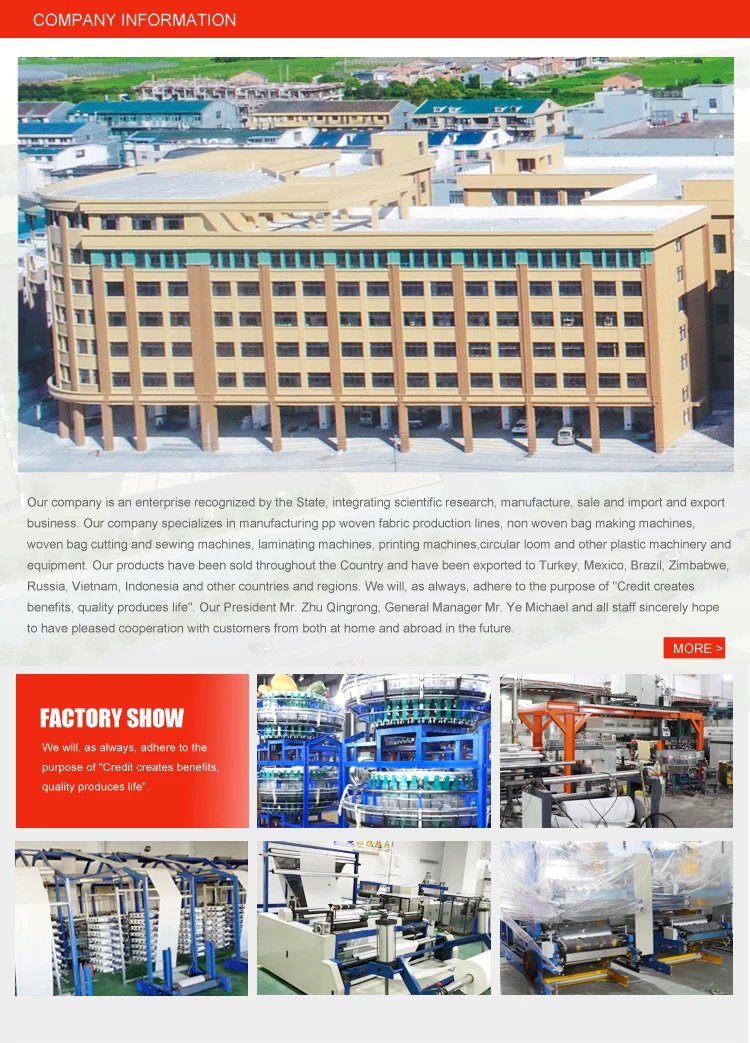

Our company is an enterprise recognized by the State, integrating scientific research, manufacture, sale and import and export business.

Our company specializes in manufacturing pp woven fabric production lines, non woven bag making machines, woven bag cutting and sewing machines, laminating machines, printing machines,circular loom and other plastic machinery and equipment. Our products have been sold throughout the Country and have been exported to Turkey, Mexico, Brazil, Zimbabwe, Russia, Vietnam, Indonesia and other countries and regions.

We will, as always, adhere to the purpose of "Credit creates benefits, quality produces life". Our President Mr. Zhu Qingrong, General Manager Mr. Ye Michael and all staff sincerely hope to have pleased cooperation with customers from both at home and abroad in the future.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian