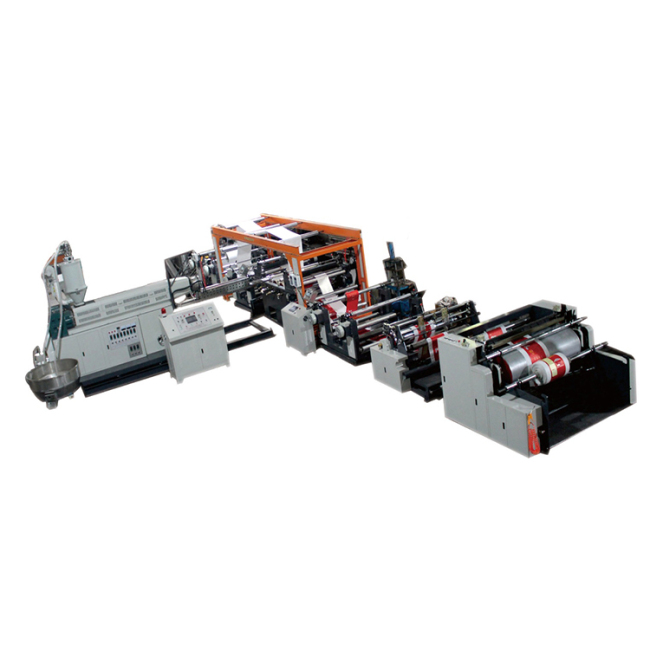

High quality PP flat yarn making machine

1-1000 Set

$75,000.00

≥ 1001 Set

$25,000.00

- Item No.2021031729acdMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

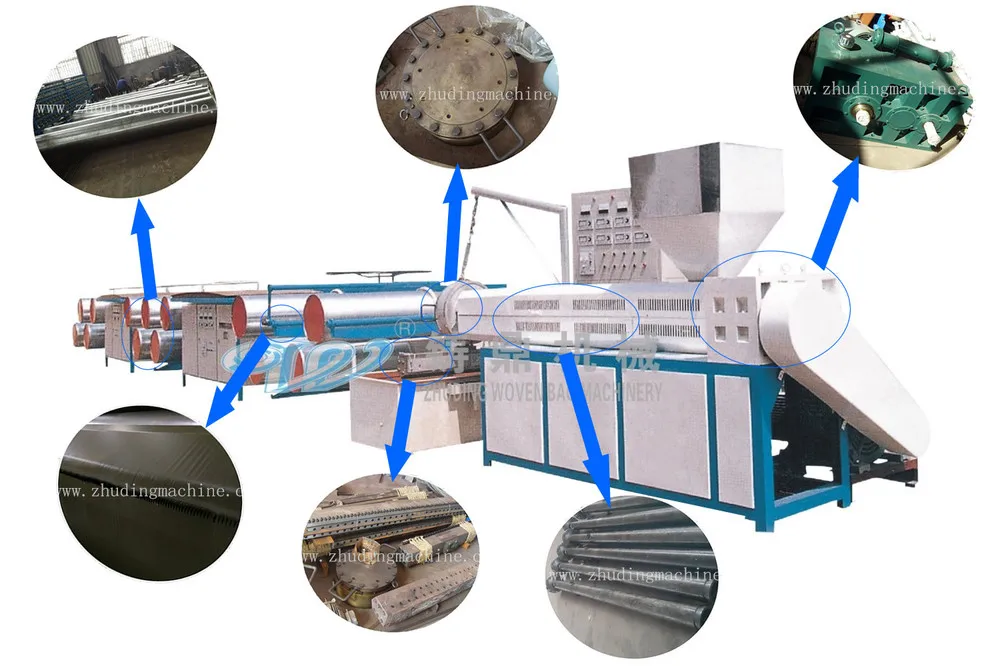

High quality pp flat yarn making machine

Performance and Characteristics:

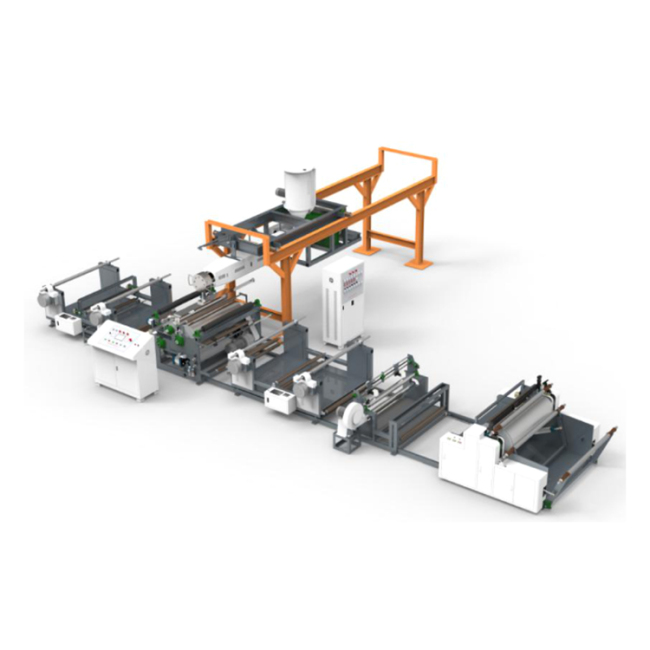

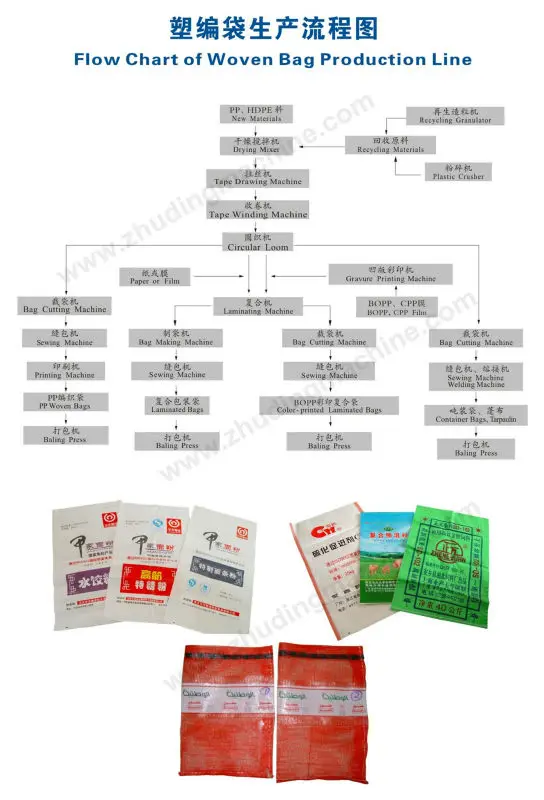

The machine using material of polypropylene & high density polyethylene, through heating extruding and drawing makes tape that is then winded for the weaving of thecircular loom.

Through our sustained improving , the machine can use 100% regenerated PP & PE ,powder or grain PP & HDPE to produce tapes .The screw and cylinder of extruder are of 38 CrMoAIA alloy steel, the hardness is over HV 950 after nitrogenation treatment. Helical gear reducer made of 20 CrMnTi Tially steel is applied to the extruder, the gears & chain wheels are made of 45# medium carbon steel and done the treatment of high frequency quench.The driving rollers are plated with hard Cr, tension self-controlling of winding-rollers are applied to the driving unit..

The cylinder of extruder, triton and die adopt aluminum cast heater which is endurable

Main Technical Parameters

Item\Type | ZD-FS | ZD-FS | ZD-FS | ZD-FS | ZD-FS | ZD-FS | ZD-FS | ZD-FS | ZD-FS |

| 110 | 110 | 110 | 120 | 120 | 135 | 135 | 140 | 140 |

length:diamete | 23:1 | 23:1 | 24:1 | 23:1 | 23:1 | 26:1 | 26:1 | 26:1 | 26:1 |

rotary speed of screw(r/min) | 25-75 | 25-75 | 25-75 | 23-70 | 23-70 | 22-65 | 22-65 | 20-60 | 20-60 |

motor power of extruder(kw) | 22 | 22 | 30 | 30 | 30 | 37 | 37 | 45 | 45 |

heating power of extruder(kw) | 33 | 34 | 36 | 43 | 47 | 77 | 80 | 86 | 92 |

| 600 | 700 | 800 | 1000 | 1200 | 1600 | 1800 | 2000 | 2200 |

| 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

power of driving motor(kw) | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 |

| 15 | 15 | 15 | 20 | 24 | 30 | 30 | 30 | 30 |

| 0.025-0.08 | 0.025-0.08 | 0.025-0.08 | 0.025-0.08 | 0.025-0.08 | 0.03-0.08 | 0.03-0.08 | 0.03-0.08 | 0.03-0.08 |

prodrction capacity(kg/h) | 30-70 | 40-80 | 50-100 | 60-120 | 70-140 | 90-180 | 100-200 | 110-220 | 120-240 |

drawing speed | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 |

| 4-8 | 4-8 | 4-8 | 4-8 | 4-8 | 4-8 | 4-8 | 4-8 | 4-8 |

| 5000 | 5500 | 6500 | 7500 | 8500 | 10000 | 11000 | 12000 | 13000 |

installing | 13300 | 13300 | 13300 | 14700 | 16500 | 17200 | 19000 | 19200 | 19200 |

http://v.youku.com/v_show/id_XNTk4ODU5OTcy.html

2014 Recent Exhibition Events

1. The 28th International Exhibition on Plastics and Rubber Industries

Date: 23 – 26 April 2014

Venue: Shanghai New International Expo Centre

Booth: E7Q61

Our Service

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

2.Clients Traning Services

We can train your staff to use your film blowing equipment systems properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

FAQ

Q:Are you factory or trade company?

A:We are factory.

Q:Where is your factory?

A:We are in Aojiang Town, Pingyang County, Wenzhou City.

Q:How far is your factory from the Ruian station?

A:Half an hour.

Q:How far is your factory from Wenzhou airport?

A:Half an hour.

Q:What do you offer after-sales service?

A:One-year warranty and maintenance of life. And we could send our engineer to customers' factory if you need.

Wenzhou Zhuding Machine Co., Ltd. is an enterprise which was recognized by the state, gathering scientific research, manufacturing, sales, import and export business as a whole.

The company was founded in 1995, All employees through the unremitting efforts of 17 years, now has developed to the factory covers an area of 35,00 square meters, 80 workers.Already get ISO9001-2008 certificate, CE certificate, factory inspection certificate .

Our company specializes in manufacturing Non woven fabric production line,non woven bag making machine, rice bag cutting and sewing machine, laminating machines, flexographic printing machine, film blowing machine, shopping bag making machines etc plastic machinery equipment. Products have sold throughout the country, as well as Turkey ,Mexico, Brazil,Zimbabwe, Russia, Vietnam, Indonesia and other overseas countries and regions.

We will, as always, adhere to the "Credit creates benifits, quality produces life" purposes. Company president Mr Zhu QingRong and G.manager Mr Ye Michael with all the staff sincerely hope to have a pleasure cooperation with customers both at home and abroad in the future.

Please send us inquiry for more informations, we will supply you good machine price & good after sales service. Thank you!

| Business Type | Manufacturer, Trading Company | Country / Region | Zhejiang, China |

| Main Products | Circular Loom,Lamination Machine,Bag Making Machine,Nonwoven Bag Making Machine,Printing Machine | Total Employees | 51 - 100 People |

| Total Annual Revenue | confidential | Year Established | 2011 |

| Certifications | CNAS | Product Certifications | Utility Model Patent Certificate ,CE,CE,CE,CE |

| Patents | Trademarks | ||

| Main Markets | Domestic Market 30% Southeast Asia 17% Africa 15% | ||

Our company is an enterprise recognized by the State, integrating scientific research, manufacture, sale and import and export business.

Our company specializes in manufacturing pp woven fabric production lines, non woven bag making machines, woven bag cutting and sewing machines, laminating machines, printing machines,circular loom and other plastic machinery and equipment. Our products have been sold throughout the Country and have been exported to Turkey, Mexico, Brazil, Zimbabwe, Russia, Vietnam, Indonesia and other countries and regions.

We will, as always, adhere to the purpose of "Credit creates benefits, quality produces life". Our President Mr. Zhu Qingrong, General Manager Mr. Ye Michael and all staff sincerely hope to have pleased cooperation with customers from both at home and abroad in the future.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian